who

we are

Few institutions can boast of bridging the gap between academics and the industry, like us.

Hailing from the S.P. Mandali Trust - one of the oldest in India; Prin. L.N.Welingkar Institute of Management Development and Research (WeSchool) has come to be known as one of the torchbearers for progressive higher education today.

Shaping the business giants of tomorrow, we run every program keeping in mind the continuously altering socio-economic world we live in.

Besides our regular management programmes, we offer programmes in Business Design, E biz, Research and Business Analytics, Rural, Retail, Healthcare, and Media and Entertainment.

Know More

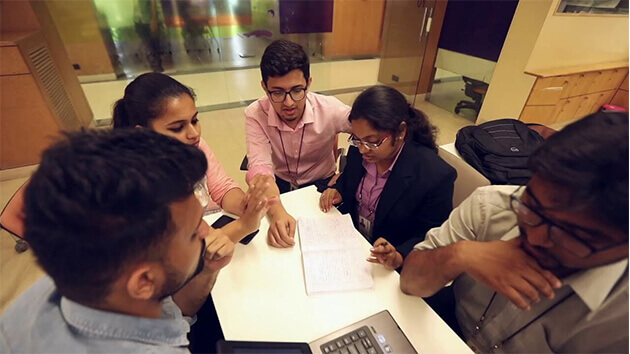

our

Our Leadership

We choose to tread the path, less travelled.

Our aspiration is, to create a fertile environment conducive to experiential learning. Our destination, a corporate revolution. With ‘design thinking’ at the heart of all our efforts, we strive towards disseminating knowledge, to create and nurture the leaders of tomorrow.

After all, there’s nothing quite like the enlightenment, gained from meaningful education.

Know More

Awards & Rankings

Over the years, through the hours of hard work put in and sheer dedication of all our faculty, students, we’ve garnered a vast array of international and national accolades.

These awards are an epitome of the academic excellence, innovative pedagogy, governance and leadership that WeSchool symbolises.

We continue to push the boundaries of what we can accomplish, through meaningful learning.

Know More

Accredited by the National Board of Accreditation (NBA) for the following programs - PGDM, PGDM E-biz and PGDM Business design (Mumbai & Bangalore campus) and MMS (Mumbai campus).

Accredited by the National Board of Accreditation (NBA) for the following programs - PGDM, PGDM E-biz and PGDM Business design (Mumbai & Bangalore campus) and MMS (Mumbai campus).

.jpg)